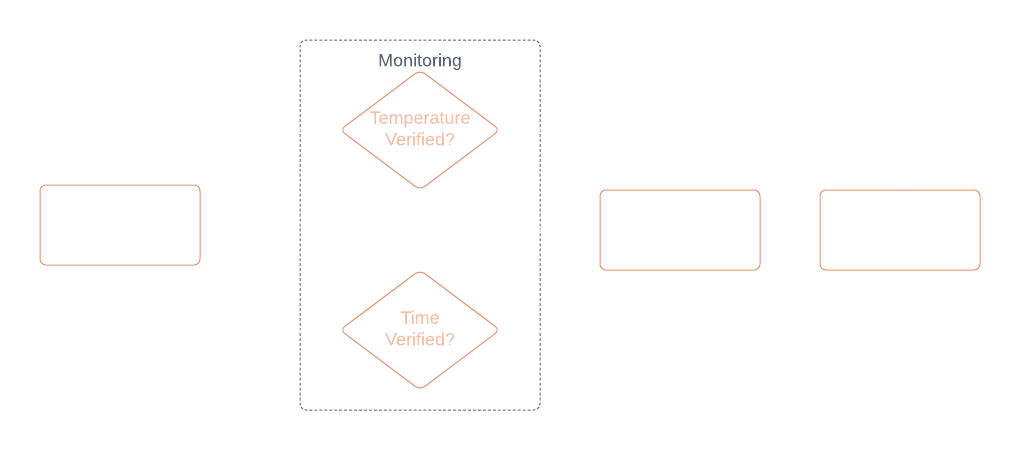

Cook Chill is one of the more complex food safety controls. Time and Temperature parameters are used to verify the food safety at micro-kill steps and micro-regeneration controls.

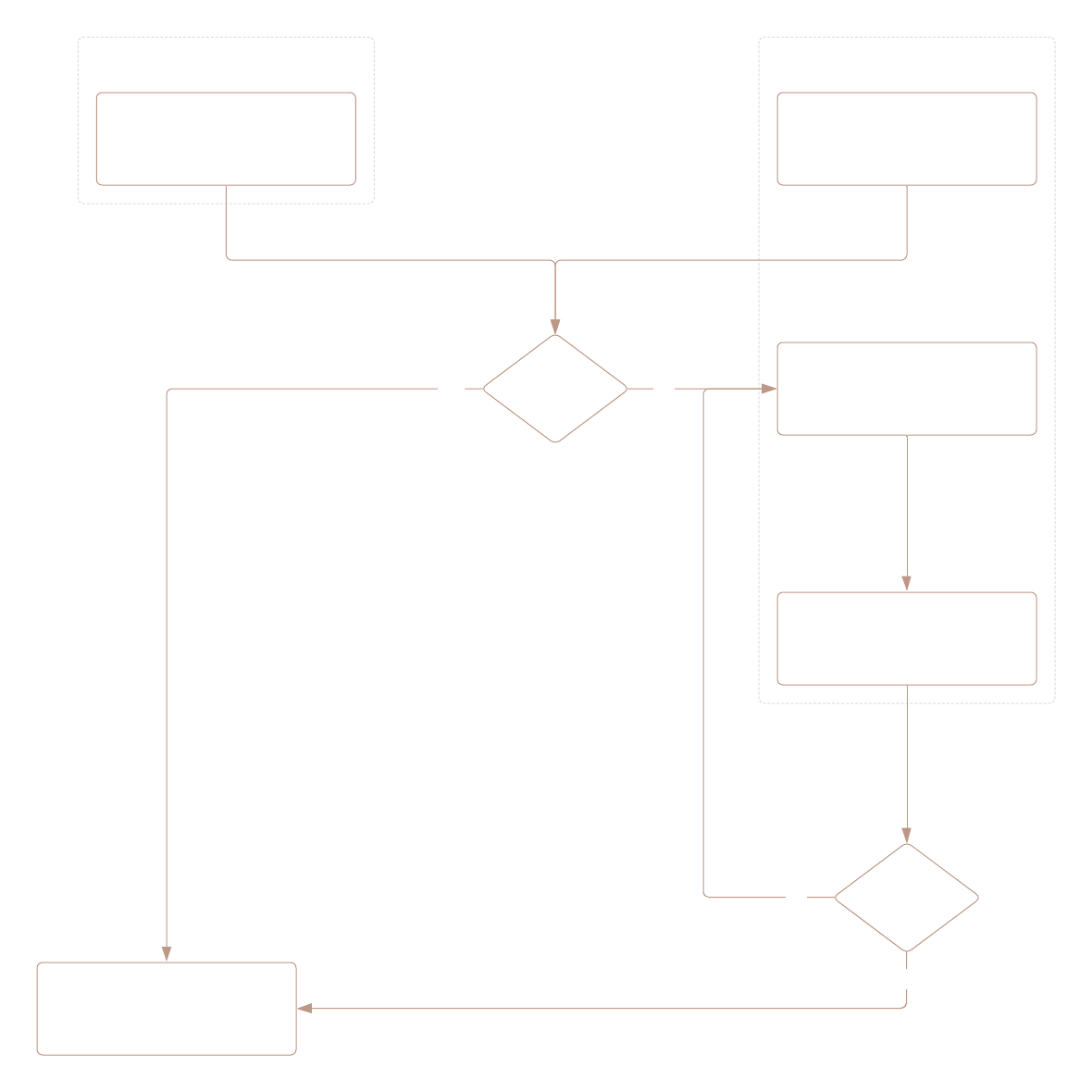

Visualising how Cold Storage monitoring flows. This is a multi-step process that requires the following data:

- Critical Limits are established, this is the temperature value that must be maintained

- Target Limits are established, this is the temperature value that should be maintained

- Corrective Actions are established, this details the actions required if Limits are breached. Both Critical Limits and Target Limits have their corresponding Corrective Actions.

- Alerts System, those receiving alerts and notification, including escalation to senior management.

The Cold Storage App is pre-configured for this flow, plus is 100% flexible for you to add steps, Smart-Forms or any other component. One glove does not fit all.

Reporting is also pre-configured to generate the following Reports:

- Temperature Graphs and Data Tables

- Corrective Actions Reports

- Cold Storage Trend Reports

Businesses can also use the Reporting Engine to build many other custom reports.

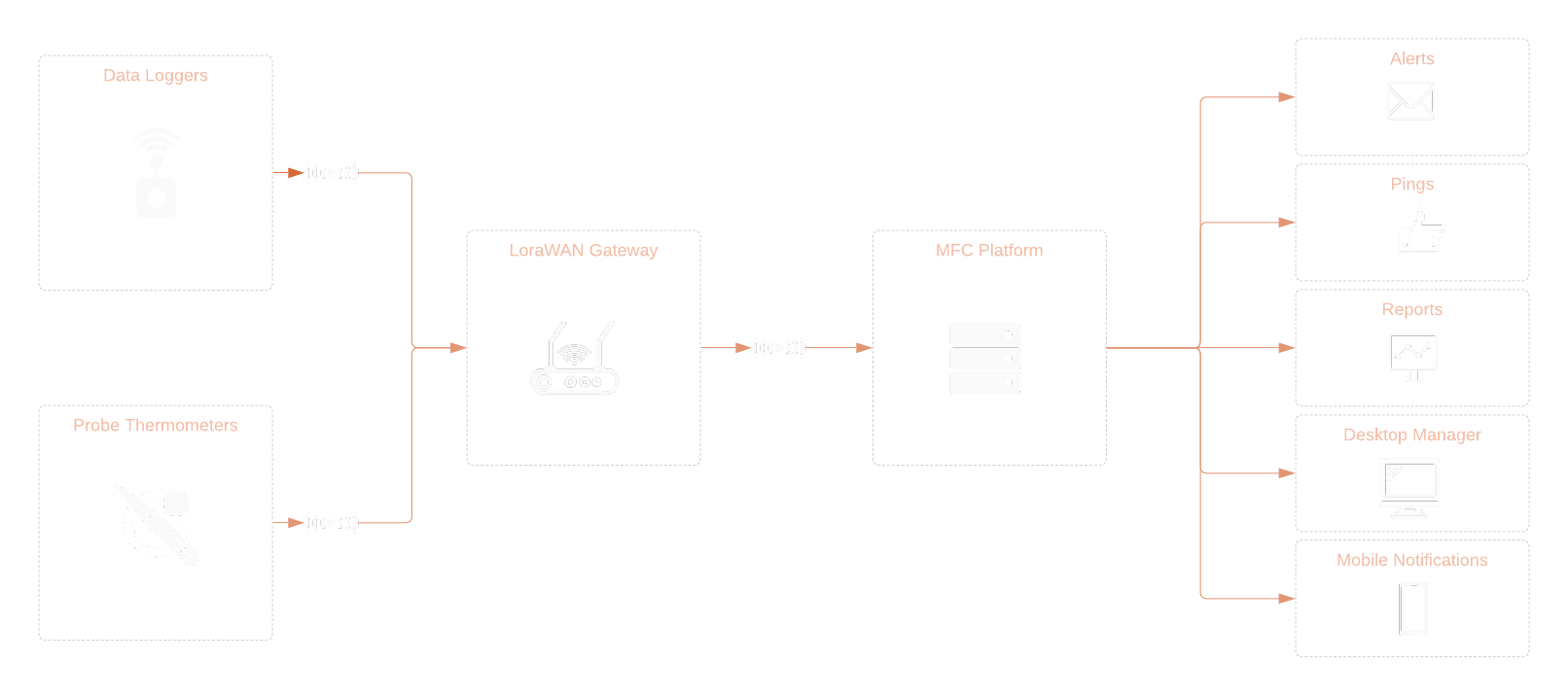

The most efficient way of monitoring Cook Chill is using automated wireless thermometers.

The MFC Platform has a huge range of compatible hardware that can be used for this purpose.

Temperature probes can simply be inserted into a product and the Cook Chill App takes care of the rest. Alerts and notifications are sent if the food is not cooling down quickly enough.All is digitally monitored and managed, with complete data logged throughout the process.

- Most effective way for Cook Chill

- MFC Platform integrate with many sensors

- Probes placed into foods for the whole journey

- Alerts & Notifications on Time & Temperature

- Widely used in Food Processing facilities

- Huge range of supported hardware in IoT

- Traceability digitally linked throughout

Simple Cook

Simple cook control is the most common way of monitoring safely cooked foods.

This method depends on a critical temperature being reached for a food, typically 75ºC. This may also be higher, depending on the business type.

Once that temperature is achieved, the microbiological condition of the food is generally considered safe.

Important to note, that the food simply must reach the temperature, it does not need to be held at that temperature for more that 1 second.

- Most common way to verify safely cooked food

- Critical temperature limit must be achieved

- Generally considered safe once achieved

- Simple temperature with no time parameters

- Can be manually entered into your app

- Wireless thermometer probes can integrate

6D Lethality Cook

More technical requirements in thermal processing of foods involve equivalent lethality rates.

This may be for control of Listeria monocytogenes or non-proteolytic C.botulinum, in combination with storage temperature to predict a foods shelf life.

The equivalent lethality rates differ depending on the target organism and food.

You are able to add custom lethality rates for any time temperature combination on the Cook Chill App.

F0-values, D-values and Z-values can all be added and integrated to customised time temperature solutions.

- Thermal processing equivalence parameters

- Commonly used for Meat, Milk & Egg thermalisation

- Automated calculations of Time & Temperature

- Alerts & Notifications on Time & Temperature

- Widely used in Food Processing facilities

- Huge range of supported hardware in IoT

- Ability to add custom equivalence rates

Sous vide is a method of cookery where the food is placed in a sealed pouch and typically cooked in a water bath.

Food safety of sous vide products relies on both time and temperature to achieve safe food.

The required time temperature values can be obtained from reliable government organisations such as the US Food & Drug Administration or AUS Victoria’s Department of Health.

The MFC Cook Chill App has pre-set time temperature values ready to use.

The App guides users through and alerts when products are ready and considered safe.

- Food in a sealed pouch then cooked in a water bath

- Critical time and temperature limit must be achieved

- Generally considered safe once achieved

- MFC App has all the timers ready to go

- Can be manually entered into your app

- Wireless thermometer probes can integrate

- Alerts once food is ready and safe

- Chill Step commonly follows after sous vide

- Pre-validation of sous vide process effectiveness is recommended

Rapid cooling controls the growth of the pathogenic growth of non-proteolytic C.botulinum.

The requirement is to cool the food as quickly as possible. The critical limits normally are:

- Phase 1: from 60ºC to <21ºC within 2 hours

- Phase 2: from 21ºC to < 5ºC within 4 hours

The MFC Cook Chill App comes complete with these parameters pre-configured. You can also update these to suit your requirements.

The Chill Step follows after the Cook Step. The Cook Chill App provides full traceability, linking and reporting for all steps in the workflow.

- Rapid cooling of food to <5ºC

- Controls non-proteolytic C.botulinum

- Automated calculations of Time & Temperature

- Alerts & Notifications on Time & Temperature

- Widely used in Food Processing facilities

- Huge range of supported hardware in IoT

- Ability to add custom chilling rates

- Traceability digitally linked throughout

The most efficient way of monitoring Cook Chill is using automated wireless thermometers.

The MFC Platform has a huge range of compatible hardware that can be used for this purpose.

Temperature probes can simply be inserted into a product and the Cook Chill App takes care of the rest.

Alerts and notifications are sent if the food is not cooling down quickly enough.

Re-therm refers to the reheating, re-thermalisation or re-generation of a chilled food to a hot food.

Foods undergoing re-therm have already been cooked and chilled, and considered ready-to-eat.

Re-therm is normally a simple process of heating the food to an acceptable temperature for customers to consume.

The MFC Cook Chill App comes complete with a Re-therm section, where target limits can be easily set, and the Re-therm process recorded.

- Refers to re-heating food for customers

- Retherm food is classed as ready-to-eat

- Easily set the minimum temperature for re-therm

- Alerts & Notifications enabled

- Both table and graph reporting

- Very quick and easy to implement

- Totally paperless

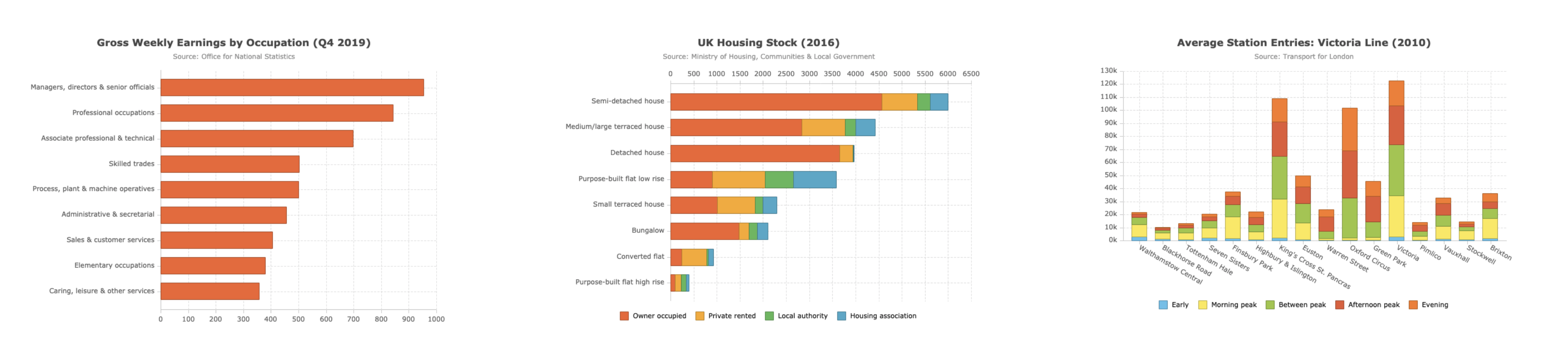

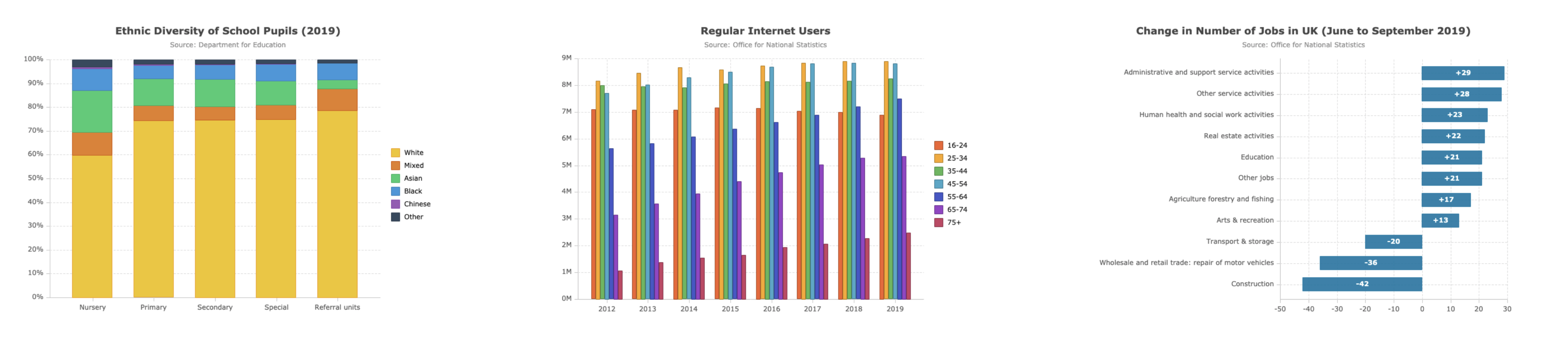

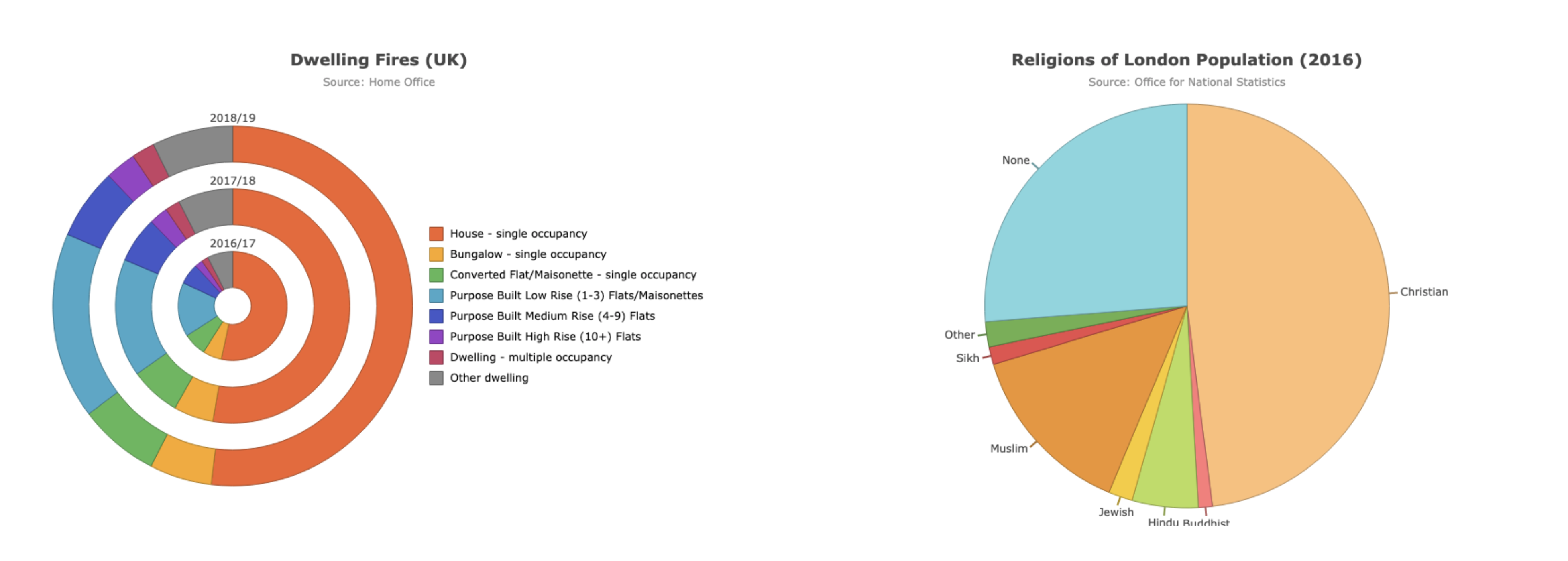

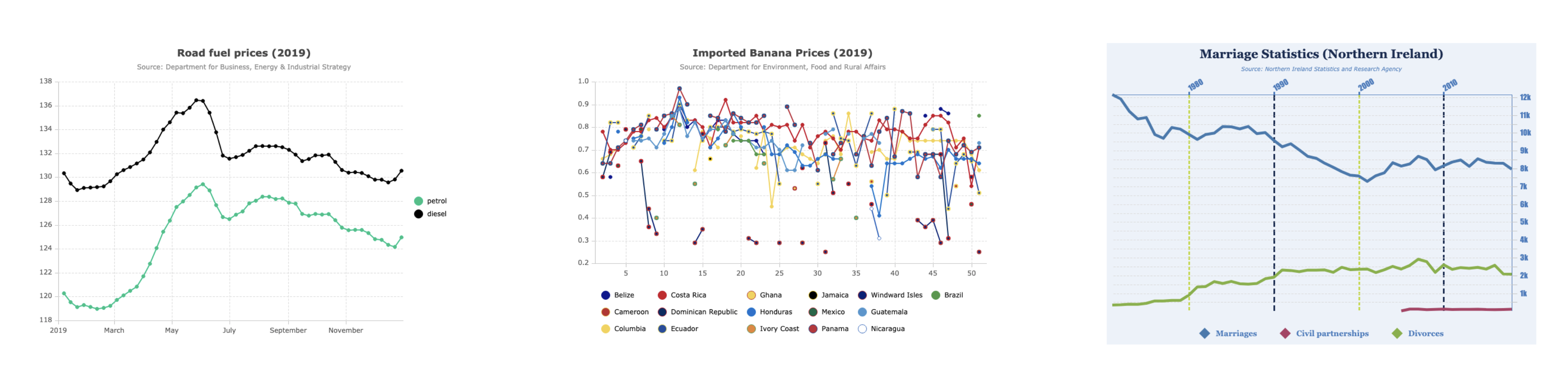

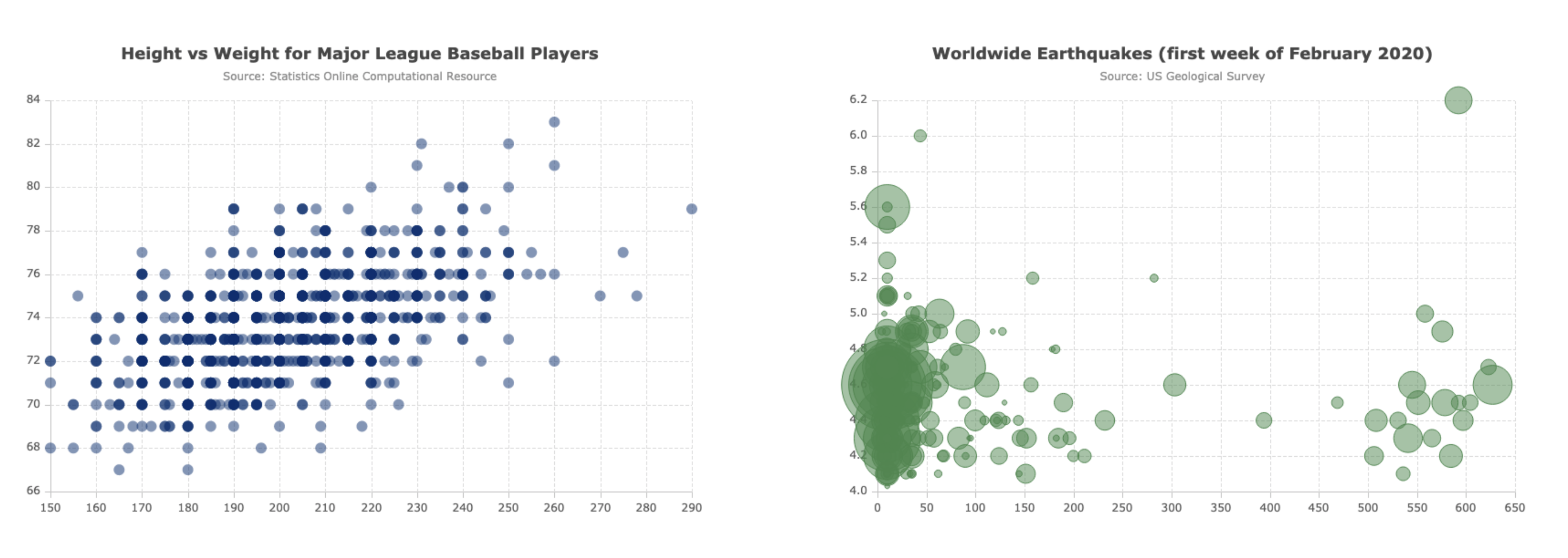

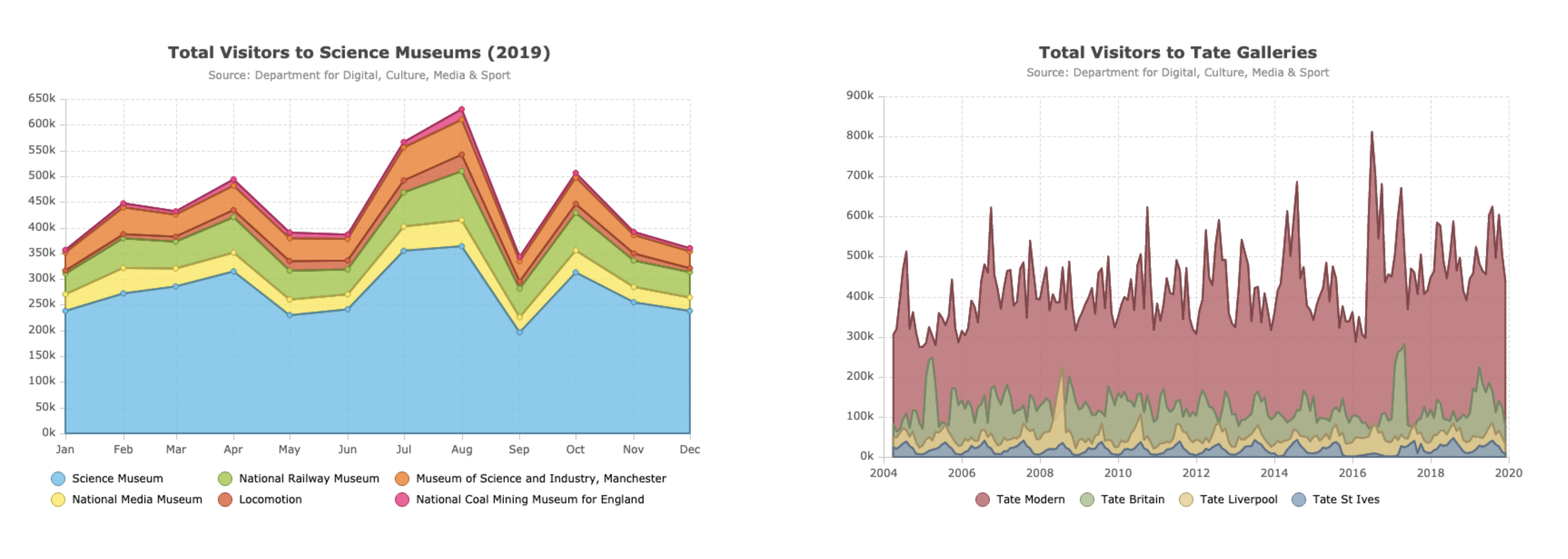

30+ data visualisation options

Business Intelligence

Enhanced Reports: a richly featured Reporting Engine enables the creation of a huge range of specialised Reports. Business Intelligence Reporting is a key aspect of truely harnessing the full value of technology in your business.

- Create any number of Reports

- Simple and complex Data Tables

- All Data Tables have Graphical Tools

- Visualise data-sets easily

- Set Report Summaries and Threshold Reports

- Aggregate and Group Data Tables

- All based on real-time technology

30+ data visualisation options

All aspects of the Cook Chill implementation are done by the MFC Team.

Gateways, sensors are all set up on your Network and Site before they are shipped to you.

Physical installation and commissioning can be either done by you or by the MFC Team. Businesses that have maintenance and engineering teams can easily install the hardware.

Pricing for the hardware (gateways, sensors, devices) is provided to you as a proposal and quotation.