MFC offers a complete and fully integrated solution for Wireless Temperature Monitoring. Cold Storage is a Critical Control Point in many supply chains that produce, handle, store and distribute temperature-sensitive products. Real-time data is paramount to controlling hazards and risks at all steps of the cold-supply-chain.

Being built on the MFC Platform, the Wireless Temperature Monitoring solution is totally customisable

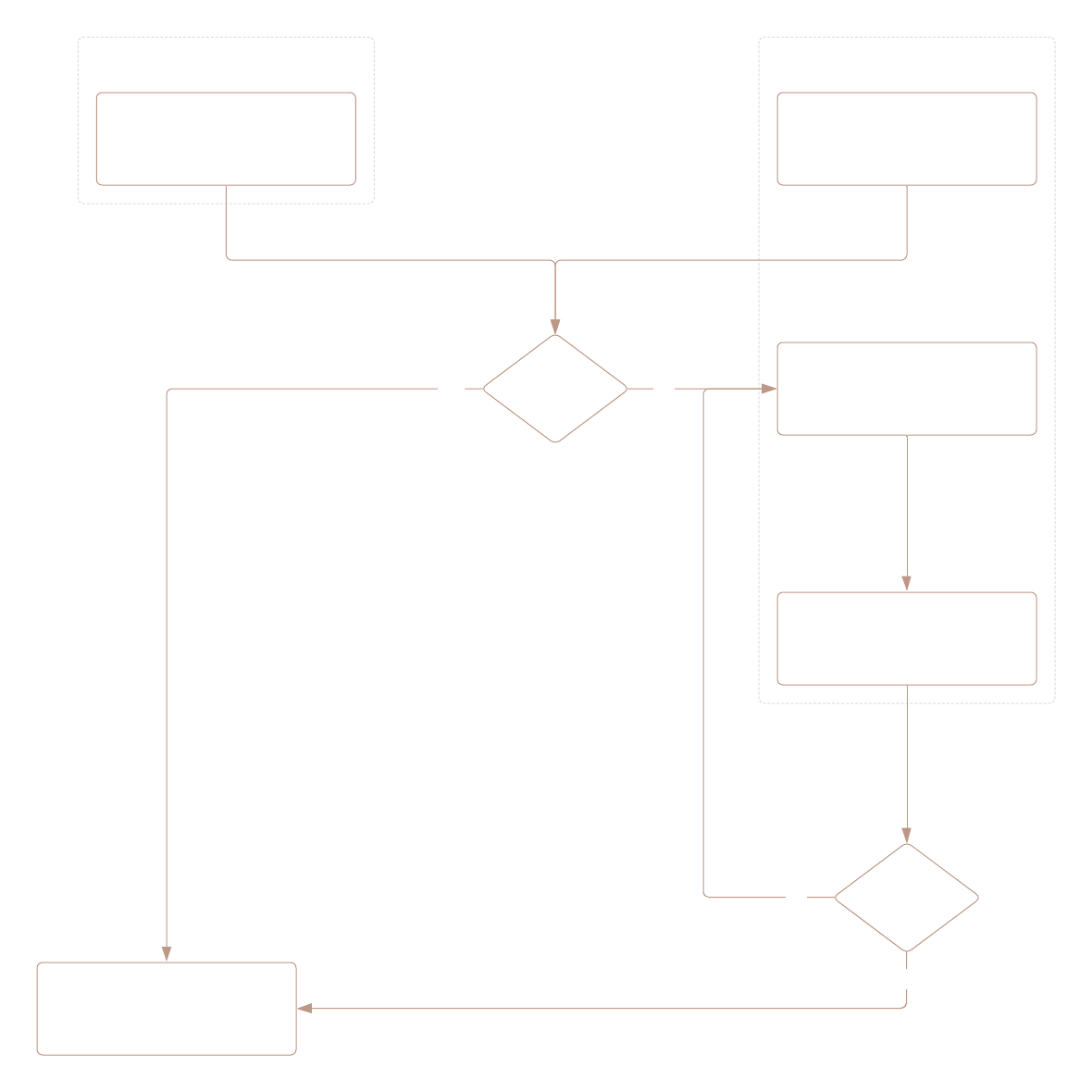

Visualising how Cold Storage monitoring flows. This is a multi-step process that requires the following data:

- Critical Limits are established, this is the temperature value that must be maintained

- Target Limits are established, this is the temperature value that should be maintained

- Corrective Actions are established, this details the actions required if Limits are breached. Both Critical Limits and Target Limits have their corresponding Corrective Actions.

- Alerts System, those receiving alerts and notification, including escalation to senior management.

The Cold Storage App is pre-configured for this flow, plus is 100% flexible for you to add steps, Smart-Forms or any other component. One glove does not fit all.

Reporting is also pre-configured to generate the following Reports:

- Temperature Graphs and Data Tables

- Corrective Actions Reports

- Cold Storage Trend Reports

Businesses can also use the Reporting Engine to build many other custom reports.

Real-time Control

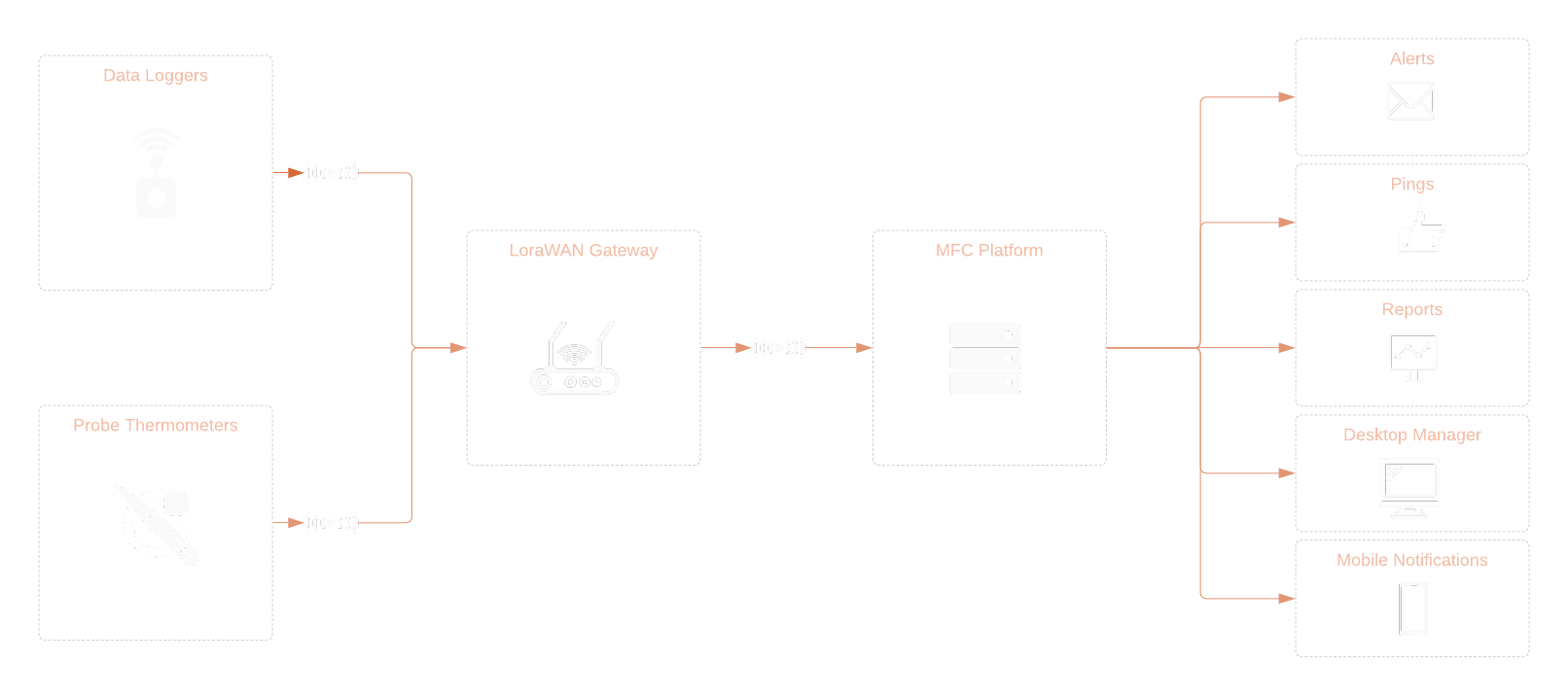

Without a doubt, using automated wireless Data Loggers & Probes are recommended for Cold Storage.

Data loggers & Probes consist of a sensor and gateway, and real-time temperature readings are generated.

Data is transmitted wirelessly to the MFC Platform, where the data is used in charts, graphs and many types of reporting.

Escalated Alerts and Notifications are enabled, where failure to apply Corrective Actions within decided timeframes push notifications up the chain of command.

Please see the Integrations section to choose your hardware.

- Superior method for Cold Storage Monitoring

- Real-time data

- Saves valuable man-power with no manual tasks

- Many report types can be set up

- Escalated Alerts & Notifications

- Huge range of supported hardware in IoT

- Data loggers for fixed sensors

- Probe thermometers for mobile sensors

Business may wish to simply manually input the Cold Storage temperatures. This method may suit simple compliance whilst being very cost effective.

These features have been developed, with temperature sliders for very easy data input into the MFC App.

If temperatures are not within Critical Limits, Corrective Actions are automatically displayed and users must enter these in.

Although not totally automated, the manual temperature logging is totally paperless and can be implemented very quickly and cost effectively.

- Manually enter Cold Storage data into app

- Simple and easy User Experience

- Corrective Actions are auto-prompted

- Alerts & Notifications enabled

- Both table and graph reporting

- Very quick and easy to implement

- Totally paperless

Temperature of the product itself is commonly required.

Typically, data loggers measure ambient temperature, which can be subject to change, due to many operational factors.

Product Simulants are used closely mimic the actual core temperature of a product in Cold Storage.

Organisations involved with high-risk, high-care environments should consider using Product Simulants, along with ambient temperature monitoring.

Hydroxy-methyl-cellulose (HMC) is commonly hydrated into a gel, then probed, and used as Product Simulant.

Product Stimulants mimic temperature of products in Cold Storage:

- Simple and easy to set up

- Provide a more accurate picture of temperature

- Used in conjunction with ambient temperature

- Not subject to as much variance as ambient temperature

- Widely used in high-risk high-care facilities

- Hydroxy-methyl-cellulose commonly used

- Gel formed, bottled and probed as Product Stimulant

There are many 100’s of devices to connect and automate many processes!

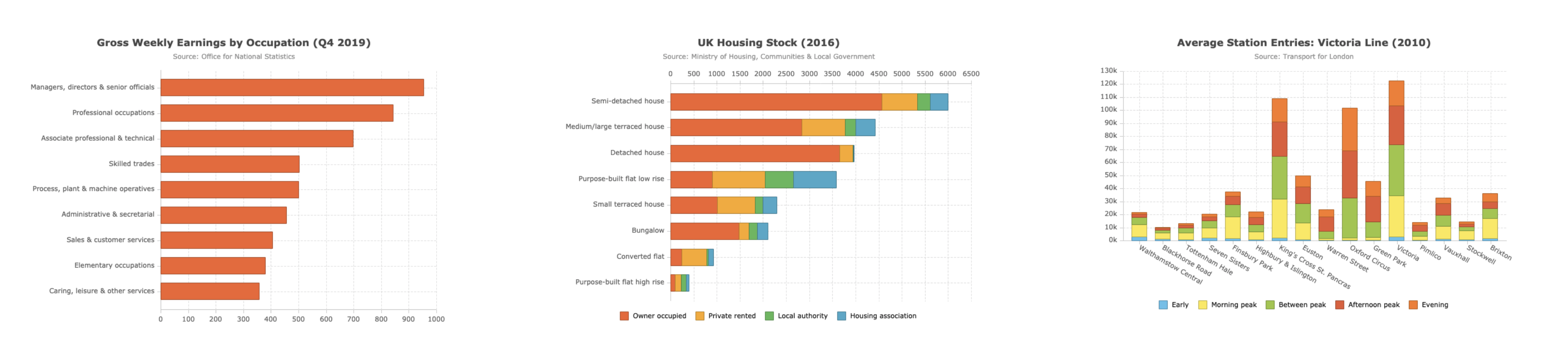

Business Intelligence

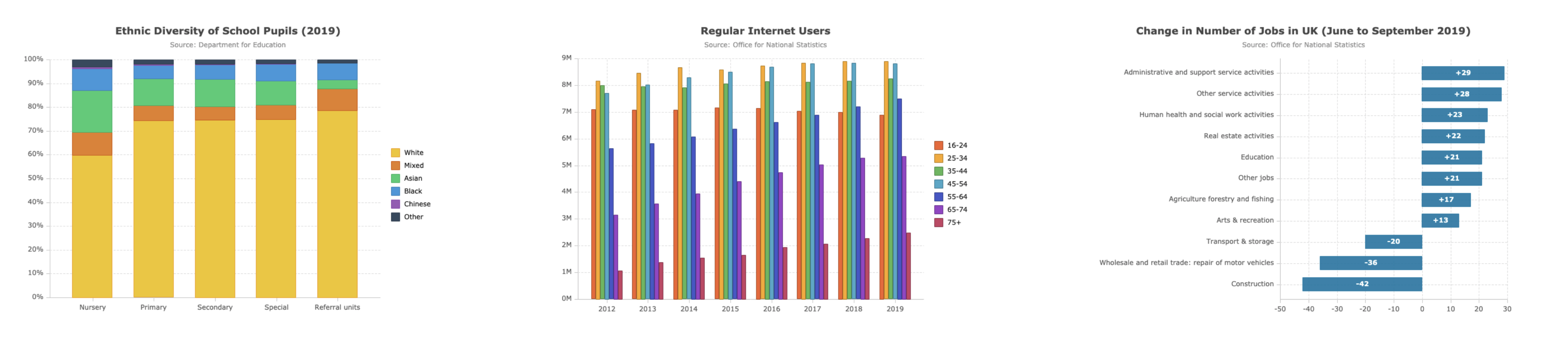

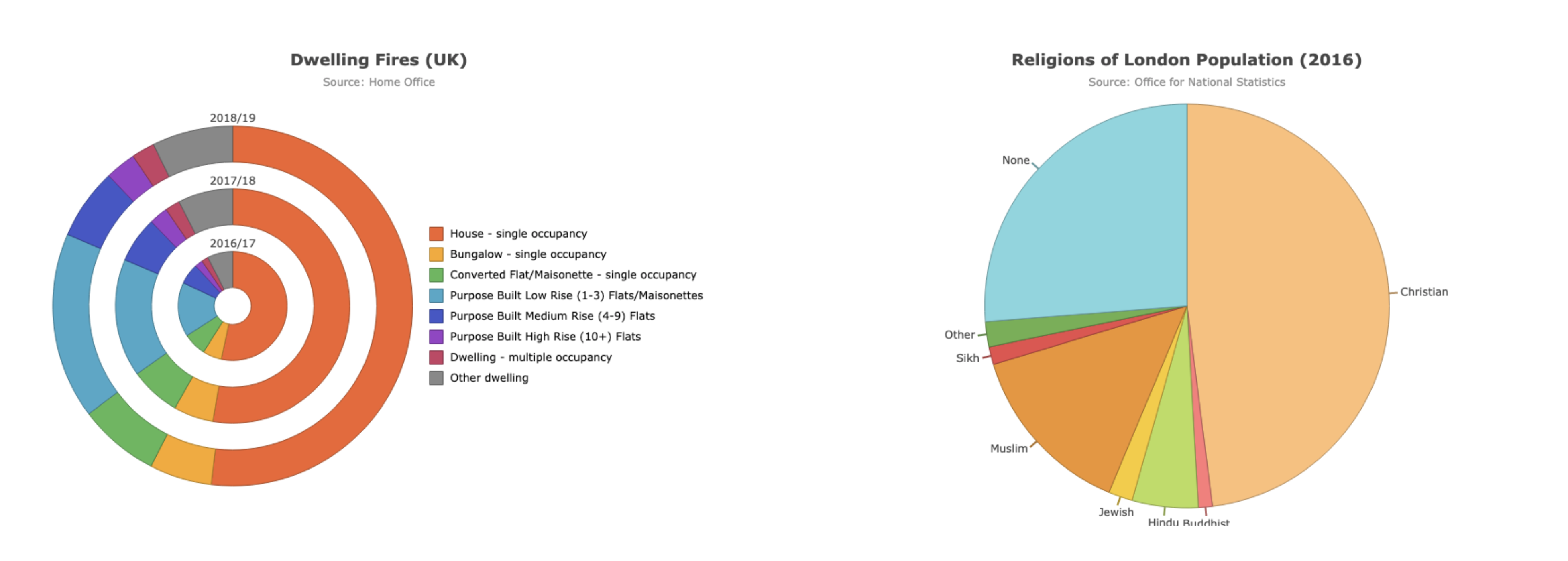

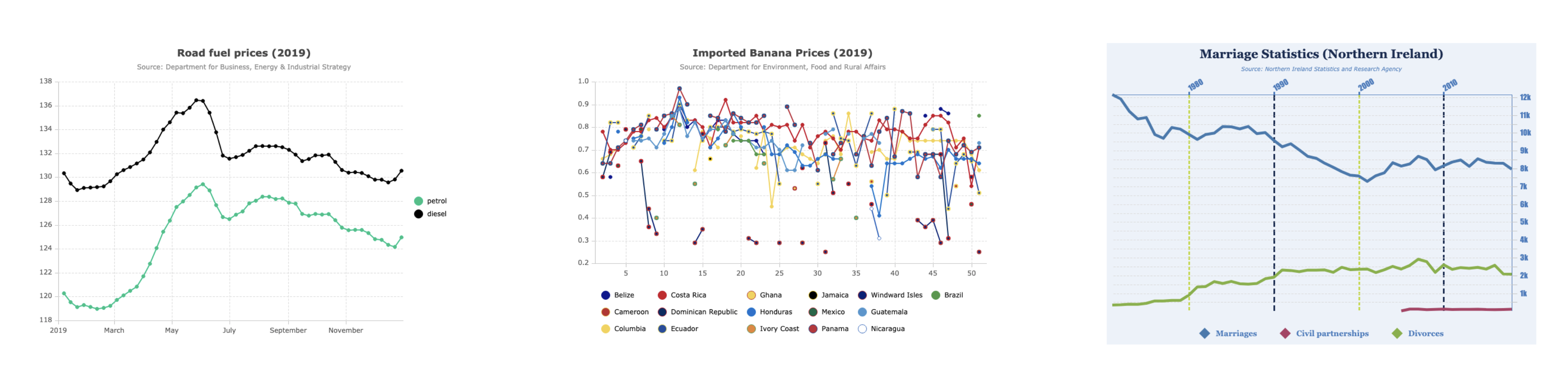

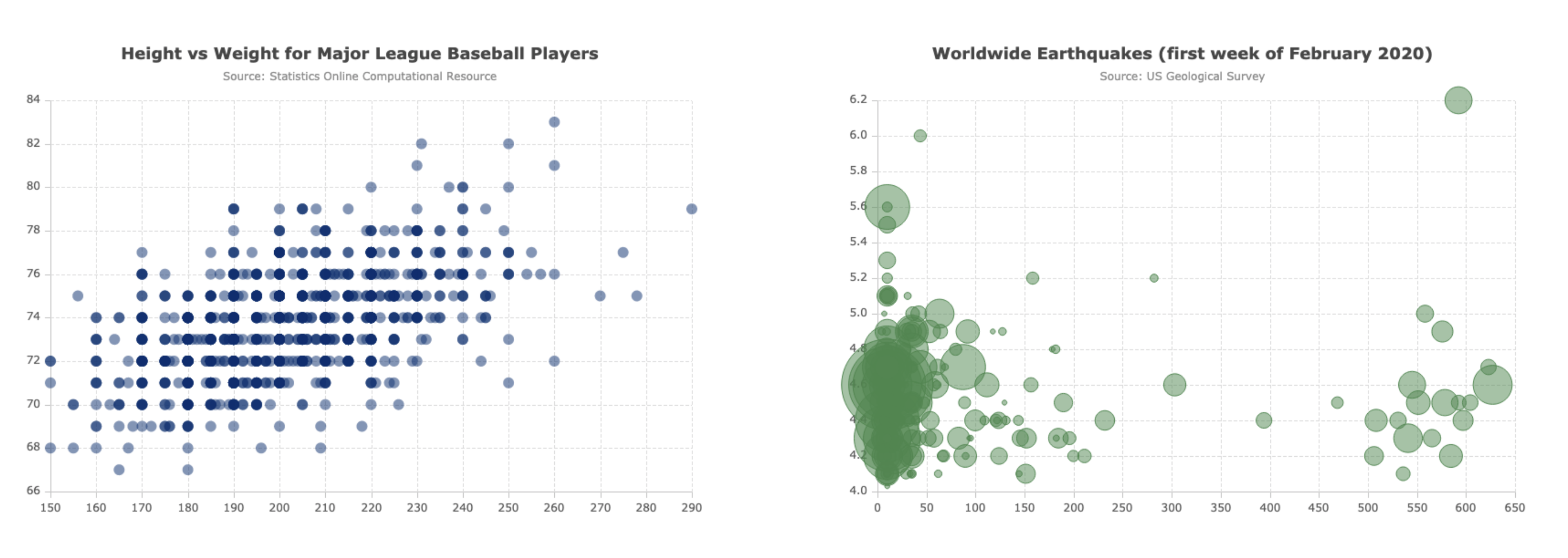

Enhanced Reports: a richly featured Reporting Engine enables the creation of a huge range of specialised Reports. Business Intelligence Reporting is a key aspect of truely harnessing the full value of technology in your business.

- Create any number of Reports

- Simple and complex Data Tables

- All Data Tables have Graphical Tools

- Visualise data-sets easily

- Set Report Summaries and Threshold Reports

- Aggregate and Group Data Tables

- All based on real-time technology

30+ data visualisation options

All aspects of the Cold Storage implementation are done by the MFC Team.

Gateways, sensors are all set up on your Network and Site before they are shipped to you.

Physical installation and commissioning can be either done by you or by the MFC Team. Businesses that have maintenance and engineering teams can easily install the hardware.

Pricing for the hardware (gateways, sensors, devices) is provided to you as a proposal and quotation.